A global CPG conglomerate saved over $75K annually in maintenance costs.

Summary

- After moving from a 12-year-old legacy CT scanner to Lumafield’s Neptune, a well-known global CPG conglomerate saved over $75K annually in maintenance costs.

- The annual maintenance included in the Neptune subscription replaced an arduous, four-day maintenance process that occurred quarterly.

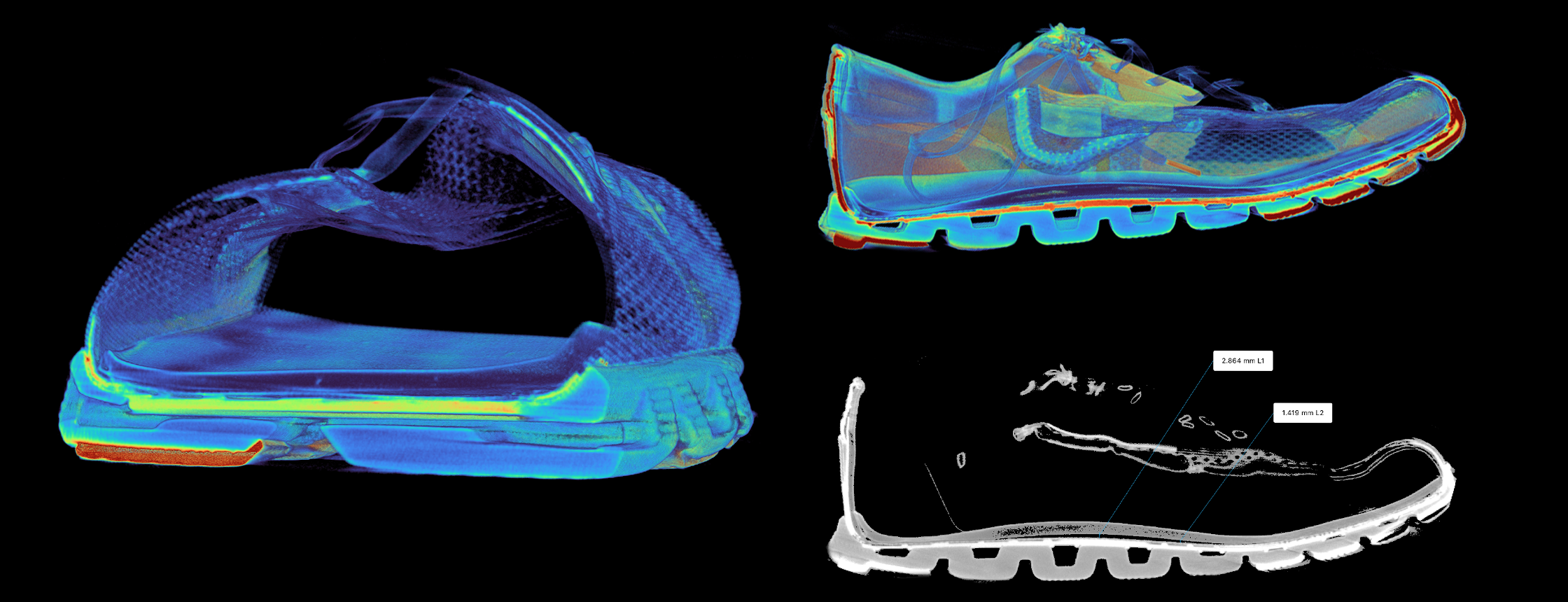

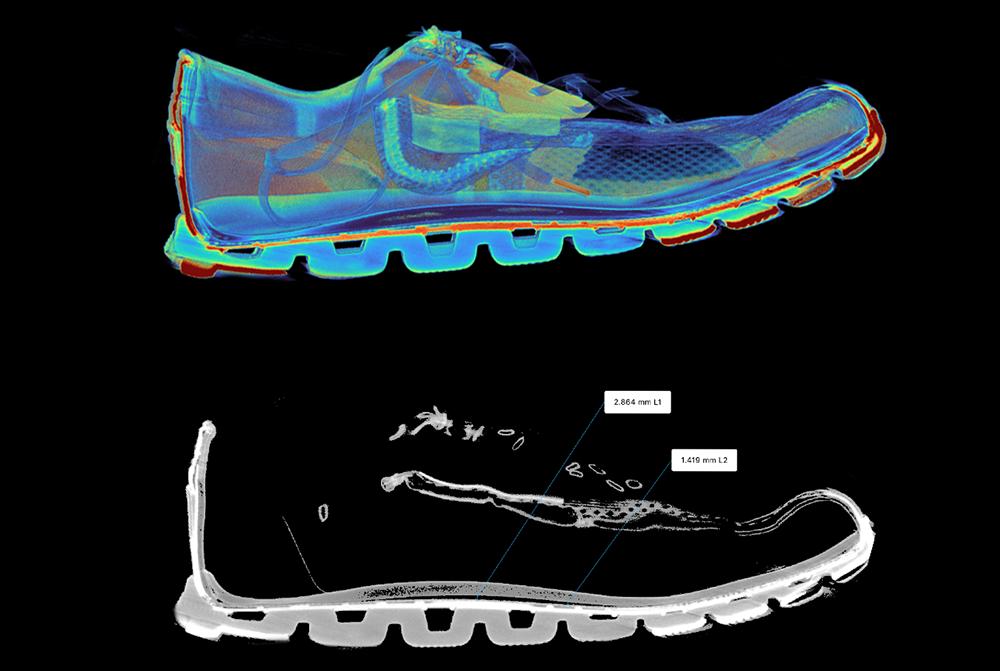

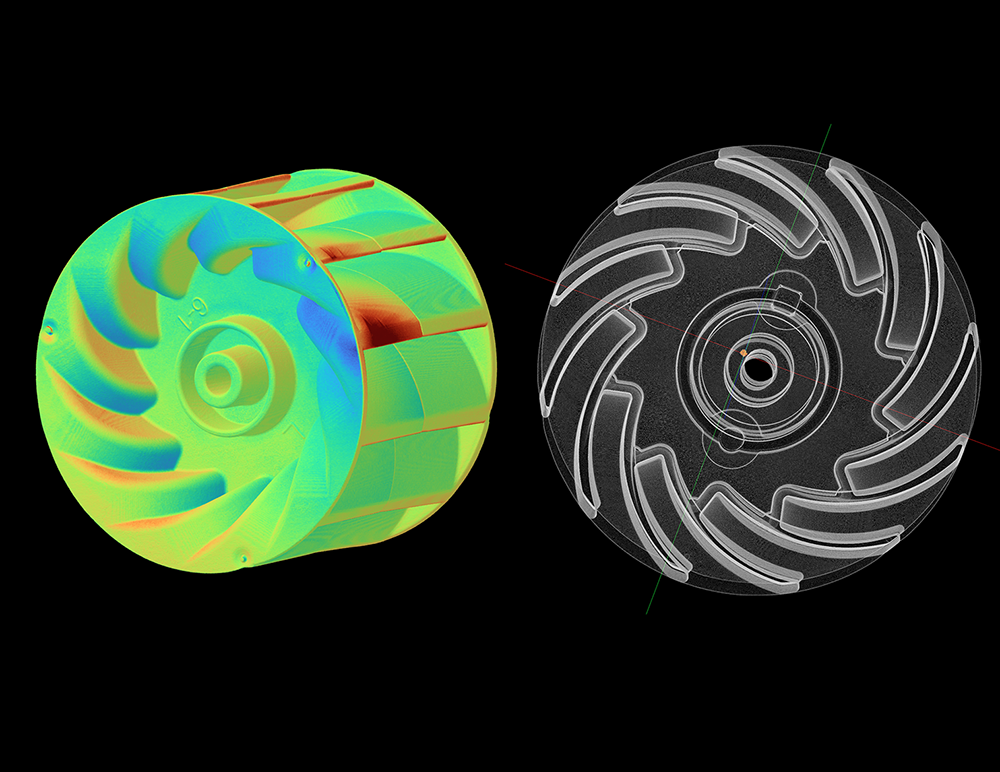

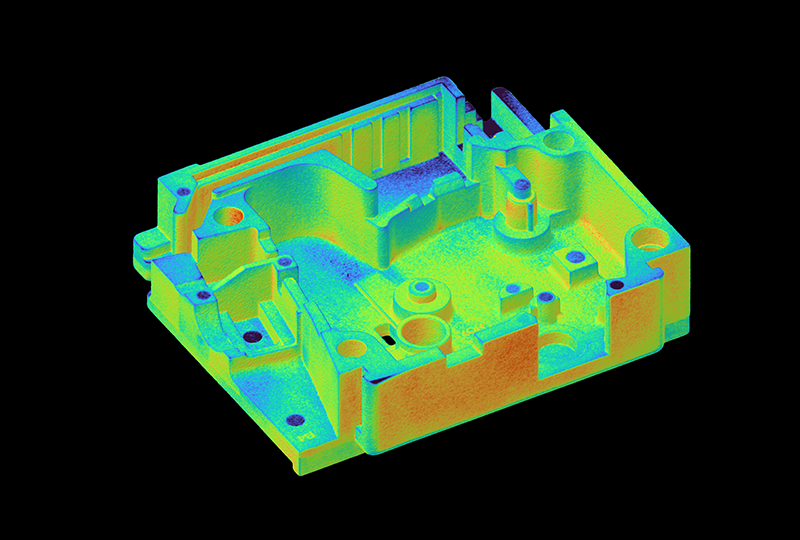

- The robust capabilities of the Neptune scanner and Voyager analysis software increased the efficiency of their failure analysis process by 34%.

- Lumafield’s technology also helped reduce the length of their product development cycle by 19% overall.

Background

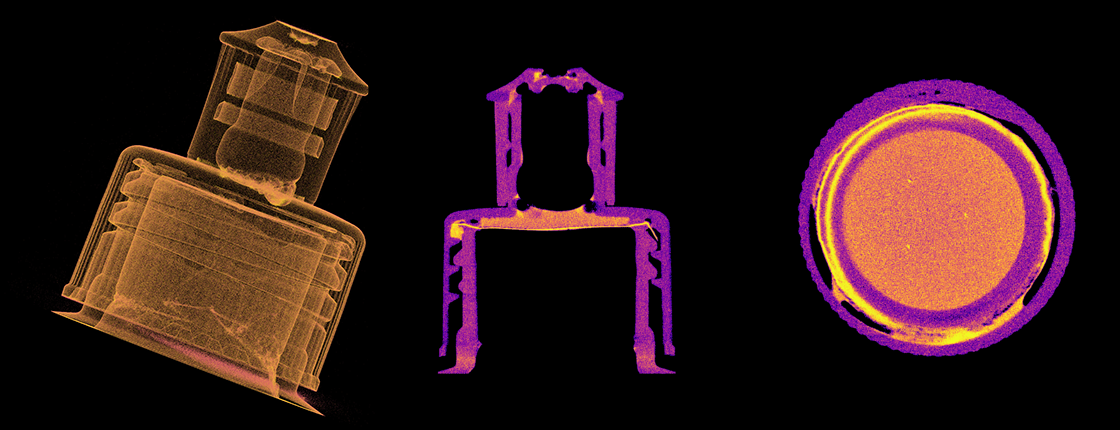

Our customer is a diversified global company with brands in categories including baby products, home goods, outdoor recreation gear, rubber storage containers, writing instruments, and more. To support the development of new products that contribute to over $8B in annual sales across their 60+ brands, the company has a state-of-the-art Research and Development lab based on the East Coast of the United States where they conduct new product development, competitive analysis, failure analysis testing, and a variety of other essential research.

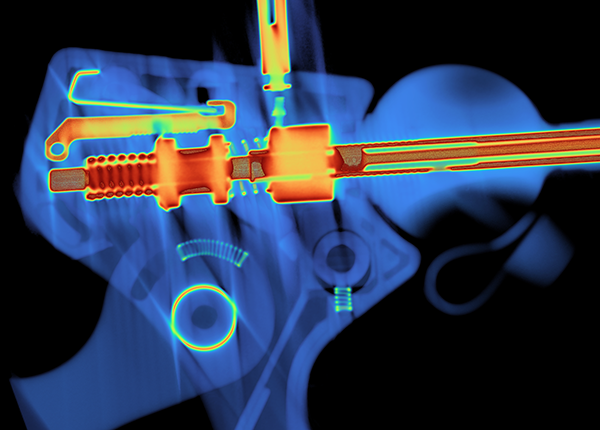

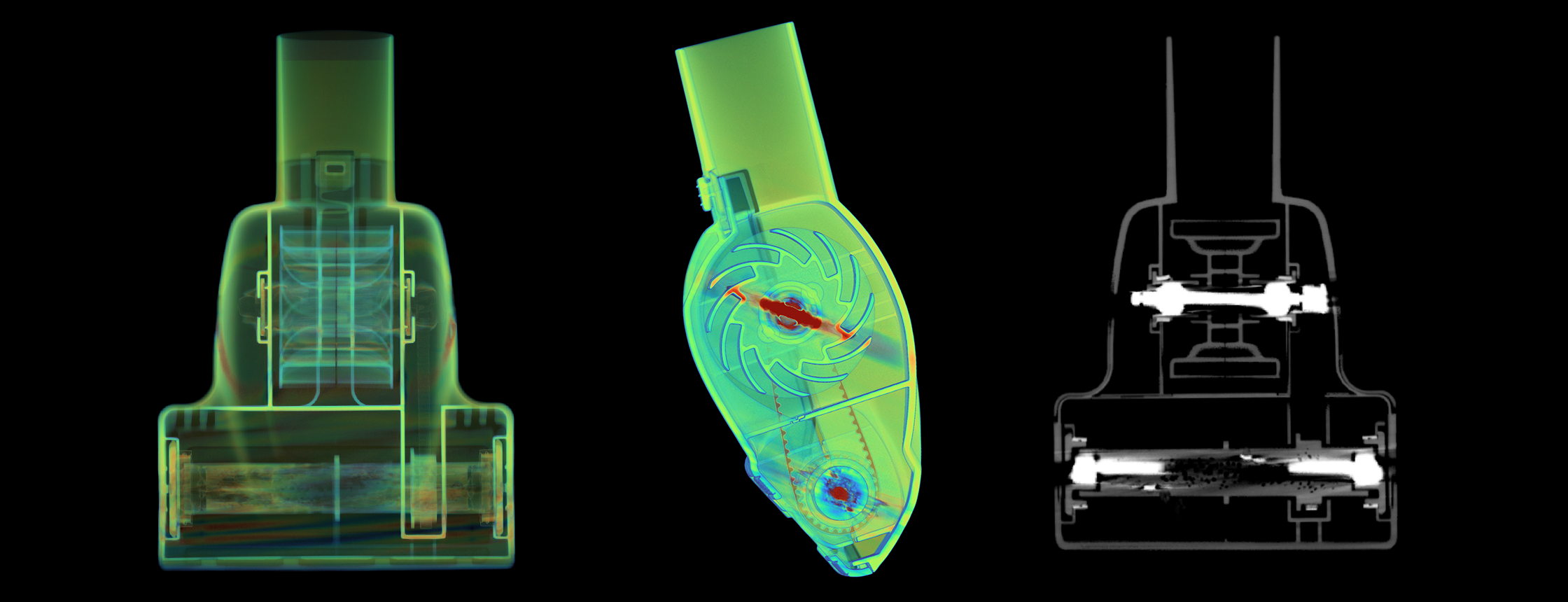

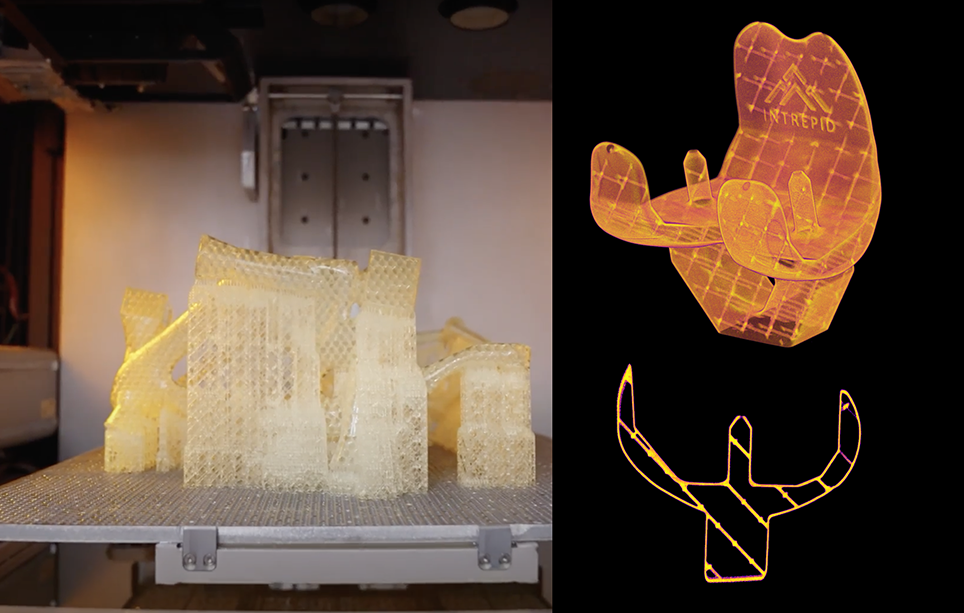

With such a wide variety of portfolio brands and products comes a lot of complexity. The product development process for this customer includes contributions from 60+ brand teams across dozens of countries with a simple goal in mind: deliver a final product that is functional and meets design intent. To analyze complex parts throughout the design process, this customer has relied on a legacy CT scanner in their R&D Center for the last 12 years.

As the R&D Center expanded to serve more of the customer’s business groups in recent years, the shortcomings of their existing legacy CT technology became more apparent. The increased volume of scans led to more breakdowns and significantly higher maintenance costs than their budget had anticipated. Not only was the machine expensive and unreliable, but it was simply not built to support the needs of the company’s distributed global workforce.

Stepping into the Future of R&D

When a failure analysis triggered by a defective part in one of their kitchen appliance products was delayed by nearly a week due to lengthy maintenance work on their existing CT scanner, this customer realized it was time to make a change. While the company had grown accustomed to working around the quarterly maintenance shutdowns, they had become costly impediments to the product testing process.

The R&D team saw the impact of Lumafield’s Neptune scanner immediately. Eliminating quarterly maintenance shutdowns saved the company nearly $50K in recurring annual expenses, in addition to the approximately $25K that they had been spending on unplanned maintenance each year.

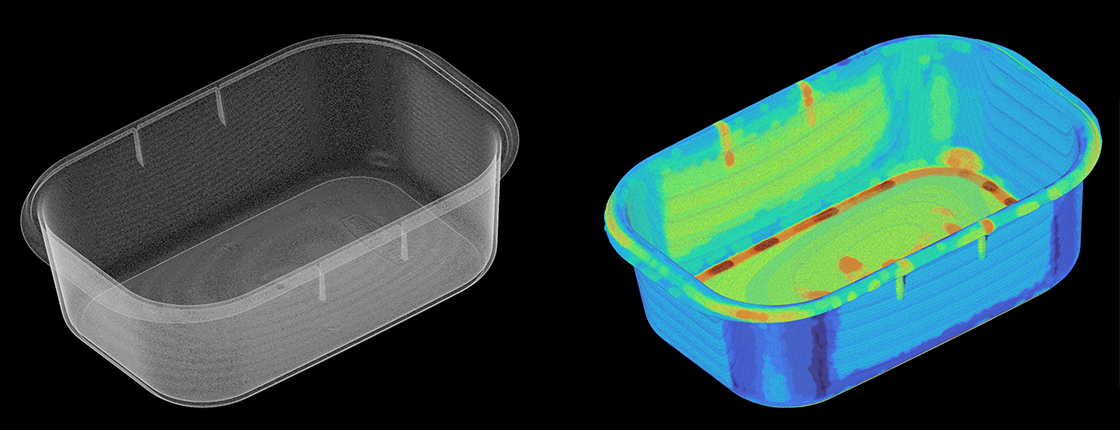

A more reliable CT scanner meant a more efficient scanning experience, and with Voyager streamlining workflows and scan analysis, the entire product development process reaped the benefits. In their first year with Lumafield, the company reported a 34% increase in the speed of their failure analyses and a 19% decrease in the length of their product development process.

While testing a new label printing product in development, the customer needed to analyze a component from a contracted manufacturer in Europe and provide feedback. “Many of our product teams were siloed for years without the ability to truly collaborate at critical points in the testing and development processes,” said the Senior Director of the company’s R&D Center. Lumafield’s Voyager analysis software allowed teams to instantly share scan data from the component and address one another’s feedback in real-time.

Voyager allows our teams halfway across the world from each other to look at the same scan data and make informed decisions – together – in real time.

— Senior Director of R&D